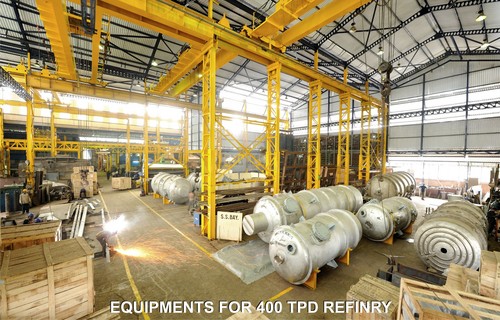

Continuous Physical Refinery Plant

Product Details:

X

Continuous Physical Refinery Plant Price And Quantity

- 1 Set

Continuous Physical Refinery Plant Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Western Union Paypal Delivery Point (DP) Cash Against Delivery (CAD) Days after Acceptance (DA) Cash in Advance (CID) Cheque

- Australia North America Eastern Europe Western Europe Middle East Africa Central America South America Asia

Product Description

Our Continuous Physical Refinery Plant is considered as the powerful plant used for continuous refining of the pretreated oil. These are engineered in variegated specifications and configurations to meet the requirements of bleaching in industry. Integrated with durable components, these plants provide long lasting performance for a long time frame. Appreciated amongst the users, our plant of Continuous Physical Refinery Plant is available at highly competitive pricing structures.

Features:

- Automatic in operations

- Easy to install

- Low maintenance cost

MERITS OF CONTINUOUS PHYSICAL REFINERY

- In order to see a rapid and efficient bleaching process of the oil, a consistent bleacher joined with a vacuum sealed bleaching earth dosing needs to be laid out.

- We offer and extra dosage of Plate heat exchangers (amongst others), so as to increase the optimum levels of recovery of the out going oil with the help of a deodoriser. This minimizes the vapour intake to the bare minimum.

- So as to utilize the most of heat which is being left out by the thermic fluid, an extra heat exchanger is supplied to the feed oil, which further reduces the load on the machine stripping system.

- Thanks to the D.O. which is in a vertical shape, the deodorisation process of oils takes place in a much more efficient and reliable manner, thus reducing the rate of steam consumption.

- The quad-stage Mazda ensures that the vacuum equipment rendered has enough vacancy(3 torr) for the procedure.

- Before supplying the oil to the main storage tanks, a three-phase filtration process is conducted so as to ensure that the liquid is of unparalleled quality.

- The two varieties of heat exchangers, namely the plate and frame type ones, are majorly utilized due to their low maintenance aspect. With less space consumption, these transfer heat more efficiently, thus making them a top choice.

- Automated running of these systems help in ensuring the faultless, glitch-free operations of such a process, with low manpower requirement.

- With the help of our team of experts, we have laid out a batch of equipments which are designed and arranged in such a manner that it offers a fantastic utilization of space, operator friendly-ness and less workforce necessity.

Enter Buying Requirement Details