Industrial Oil Refinery

Industrial Oil Refinery Specification

- Type

- Industrial Oil Refinery

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Dimension (L*W*H)

- Customizable

- Color

- Silver/Grey

Industrial Oil Refinery Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Delivery Point (DP), Cash on Delivery (COD), Cheque, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Days after Acceptance (DA), Cash in Advance (CID), Cash Advance (CA)

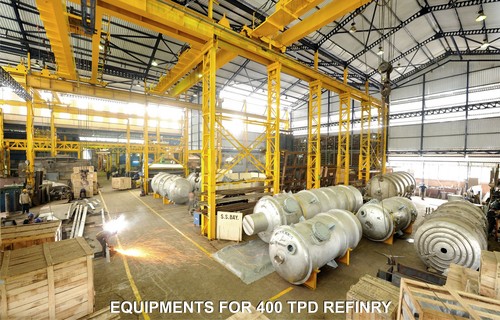

About Industrial Oil Refinery

We are a quality conscious enterprise, successfully engaged in manufacturing, exporting and supplying best grade Industrial Oil Refinery. This refinery is manufactured with the use of superior quality components and innovative techniques as per industrial quality standards. It is used for purification of oil with its proper bleaching, neutralization and deodrizing. In addition to this, the offered Industrial Oil Refinery can be availed at reasonable prices from us.

Features:

- Smooth operations

- Easy to set-up

- Hassle free functioning

- Longer service life

Oil Refinery

Oil refineries have played a pivotal role in the industries of today. Being intricately designed by the best of professionals, these systems have the ability to completely refine, degum / neutralize, bleach, strip and deodorize seed oils. The first step of this process includes the Degumming / Neutralizing System, In this level, the machines will generate oil which has low residual phosphatide content, and will be low on residual particles. Due to these low levels, the need for bleaching is least for this section. The process, once completed, provides deodorized oil, which has a light color and an exceptional shelf life. One can notice this process with the design that has been illustrated on the drawing. The bleaching procedure which we carry out is carried out based on a treatment system, which is soon followed by a filtration activity. Our extremely efficient working structure helps us to deodourise neutralized oils along with FFA oils, both of which are a part of manual refining process.

Advanced Refinement Technology

The refinery utilizes sophisticated processes to transform crude oil into deodorized, refined oil suitable for a diverse range of industrial uses. Its PLC-based control system ensures optimal precision, safety, and simplified operation. The computerized automation not only streamlines monitoring but also helps maintain consistent output quality.

Durability and Efficiency You Can Rely On

Built with high-grade mild steel and featuring robust corrosion resistance, our refinery system guarantees longevity and minimal maintenance. High operational efficiency is achieved thanks to finely tuned machinery and superior design, making it a cost-effective investment for industrial oil processing needs.

Flexible Fuel and Customization Options

Whether your operation requires electricity, diesel, coal, or biomass as a fuel source, this refinery adapts seamlessly. With customizable dimensions and a modern silver/grey finish, it is tailored to match unique spatial and production demands for diverse industrial sectors across India and beyond.

FAQs of Industrial Oil Refinery:

Q: How does the refinery process crude oil into refined, deodorized oil?

A: The refinery employs advanced purification and deodorization technologies, orchestrated by a PLC-based automated system. Crude oil undergoes sequential stagessuch as distillation, neutralization, bleaching, and deodorizationresulting in consistently high-grade, odor-free refined oil.Q: What are the main benefits of choosing this industrial oil refinery?

A: Key benefits include high operational efficiency, low noise levels, and a corrosion-resistant mild steel framework. The fully automatic, computerized PLC system enhances productivity while the robust design ensures durability, making it ideal for demanding industrial environments.Q: When is installation service provided for the refinery?

A: Installation service is offered upon purchase, ensuring that every unit is professionally set up by skilled technicians. This guarantees smooth commissioning and a hassle-free transition to full-scale operation.Q: Where can the refinery be installed and utilized?

A: This industrial refinery is suitable for installation within various industrial premises, particularly those dealing with large-scale oil processing. Since the dimensions are customizable, it can be adapted to fit diverse facility layouts across India and international markets.Q: What type of raw materials and fuels can the refinery handle?

A: Designed primarily for processing crude oil, the refinery is compatible with multiple fuel sources including electricity, diesel, coal, and biomass, thus offering flexibility according to resource availability and cost considerations.Q: How does the refinery ensure durability and corrosion resistance?

A: The main structure utilizes premium grade mild steel treated for corrosion resistance. This construction choice, combined with superior engineering, enables the system to withstand corrosive industrial environments and ensures longevity.Q: What kind of after-sales service and support are available?

A: Comprehensive after-sales services are part of the offering, covering maintenance, troubleshooting, and technical support to ensure continuous, reliable operation and client satisfaction post-installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Edible Oil Refinery Plant Category

Continuous Physical Refinery Plant

Minimum Order Quantity : 1 Set

Product Type : Continuous Physical Refinery Plant

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese